Choosing the Right Sustainable Packaging — What Fits Your Product Best?

When it comes to sustainable packaging, there’s no one-size-fits-all solution.

Each material has its own strengths — what matters is finding the right balance between performance, cost, and environmental impact.

Here’s a quick comparison of some of today’s most promising alternatives:

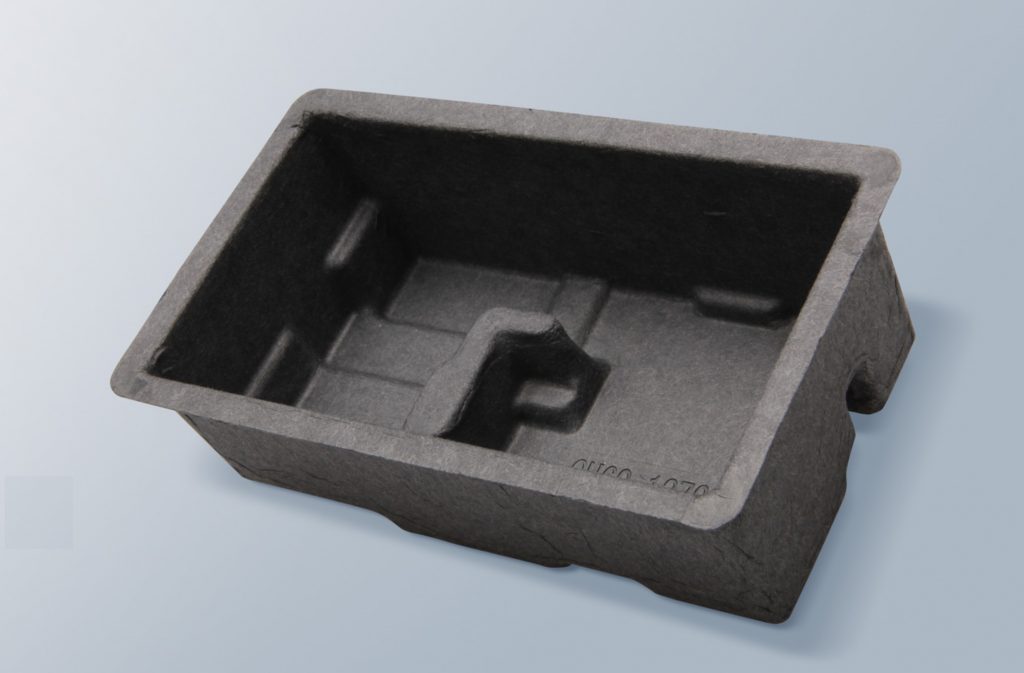

1️⃣ Molded Pulp

Made from: recycled paper or cardboard fibers.

Best for: protective transport trays, egg packaging, industrial and food applications.

Pros: highly recyclable, low cost, proven at scale.

Limitations: rough surface finish, limited design freedom, not ideal for premium products.

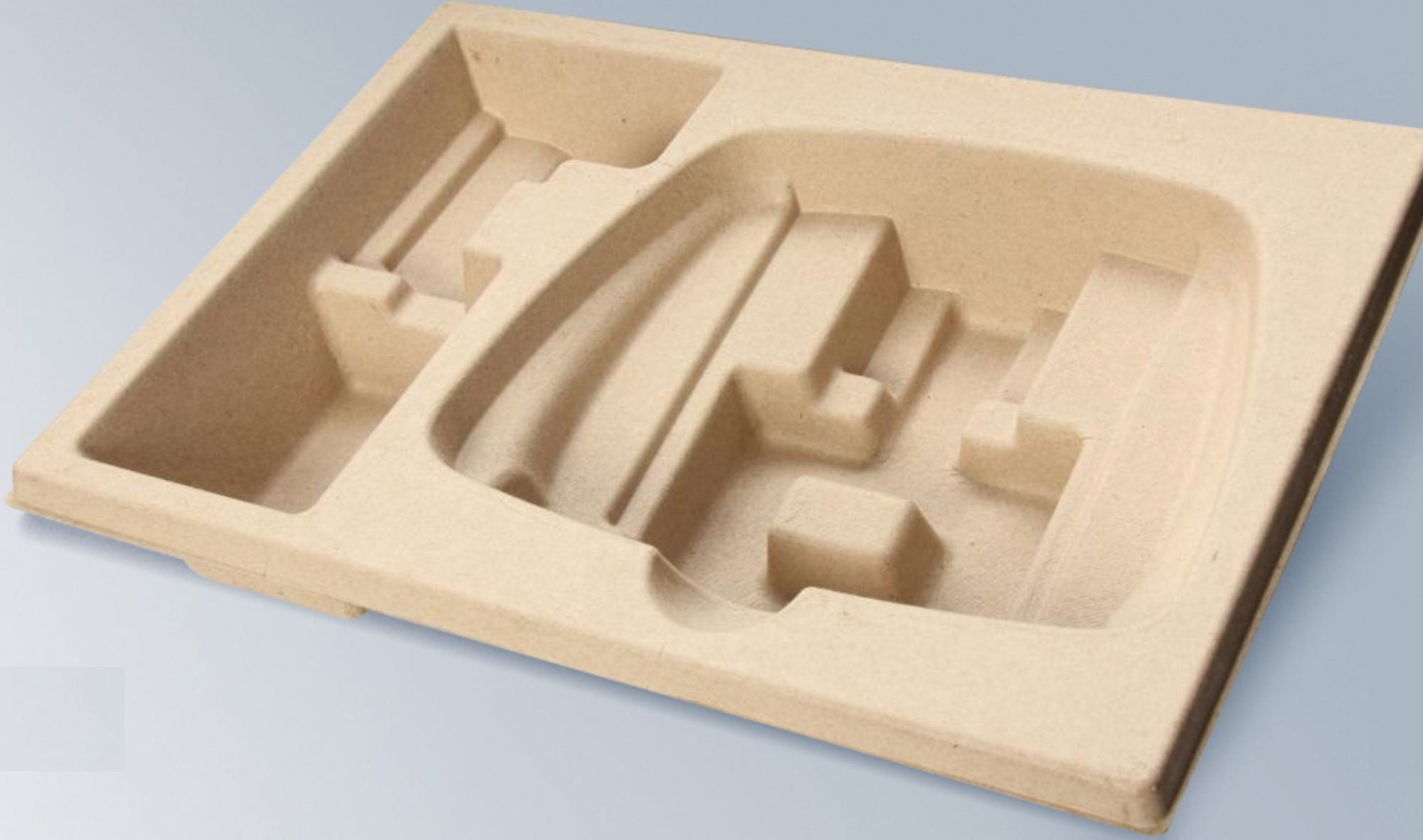

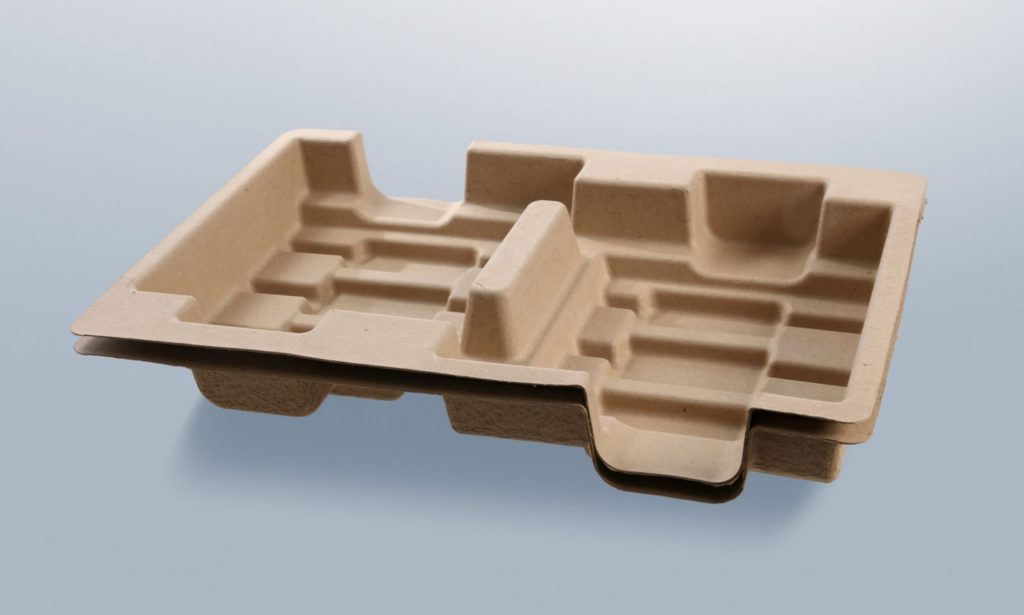

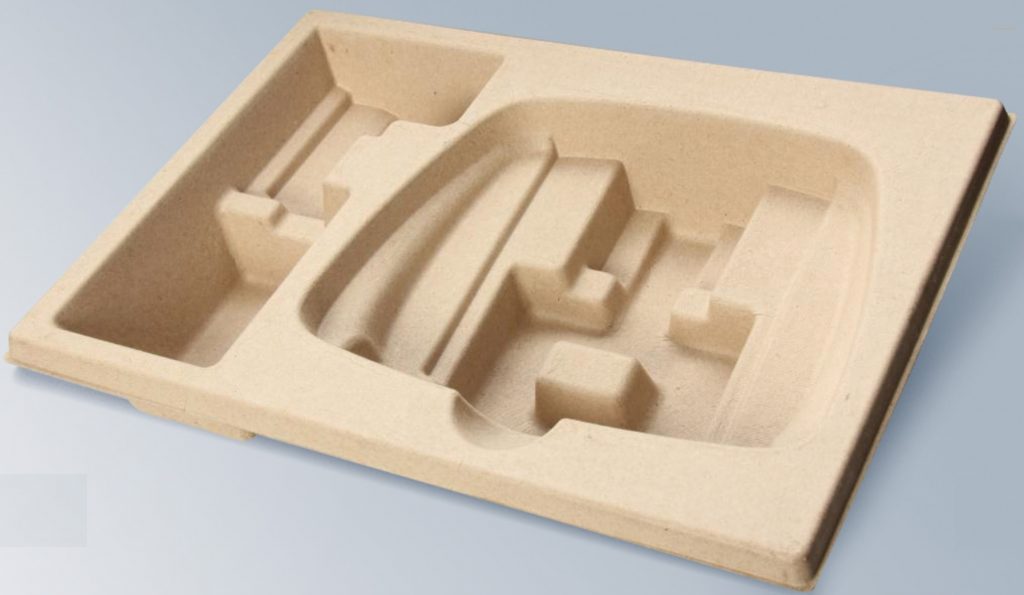

2️⃣ Thermoformed Molded Fiber

Made from: refined cellulose fibers with thermoforming technology.

Best for: cosmetics, electronics, and consumer goods that need a smooth, aesthetic surface.

Pros: premium appearance, customizable shapes, compostable.

Limitations: higher tooling cost, less suitable for heavy protective packaging.

3️⃣ EcoMolding Pulp or Fiber

Made from: potato starch, fibers, and water — baked into precise shapes.

Best for: electronics, cosmetics, and medical devices.

Pros: ultra-light, precise fit, excellent branding potential, compostable and recyclable.

Limitations: requires custom tooling and baking process — better for medium to large production runs.

4️⃣ Injection-Molded Bio-Composites

Made from: plant-based resins or recycled biopolymers.

Best for: reusable items, structural parts, or cases needing precision and durability.

Pros: mechanical strength, design freedom, precision engineering.

Limitations: energy-intensive process, less circular than fiber-based materials.

5️⃣ Textile-Based Reusable Packaging (KIUD)

Made from: upcycled textile waste, turned into a durable composite.

Best for: reusable logistics systems, retail, and e-commerce deliveries.

Pros: circular, long lifespan, washable, strong branding story.

Limitations: higher upfront cost — works best in closed-loop systems.

So… which is best?

- For protective shipping and low cost: Molded pulp wins.

- For aesthetic packaging and retail displays: Thermoformed molded fiber or PaperFoam.

- For durable, reusable loops: KIUD textile-based systems.

- For precision-engineered components: Injection-molded bio-composites.

The truth is — the future of packaging isn’t one material, but a smart mix of technologies that together eliminate waste and build circular value chains.

At Pakeling, our mission is to help brands choose the right material for their sustainability goals — from Italy to Germany, and across Europe.