Key Benefits of Molded Fiber Packaging & More…

Sustainable Innovation in Every Shape

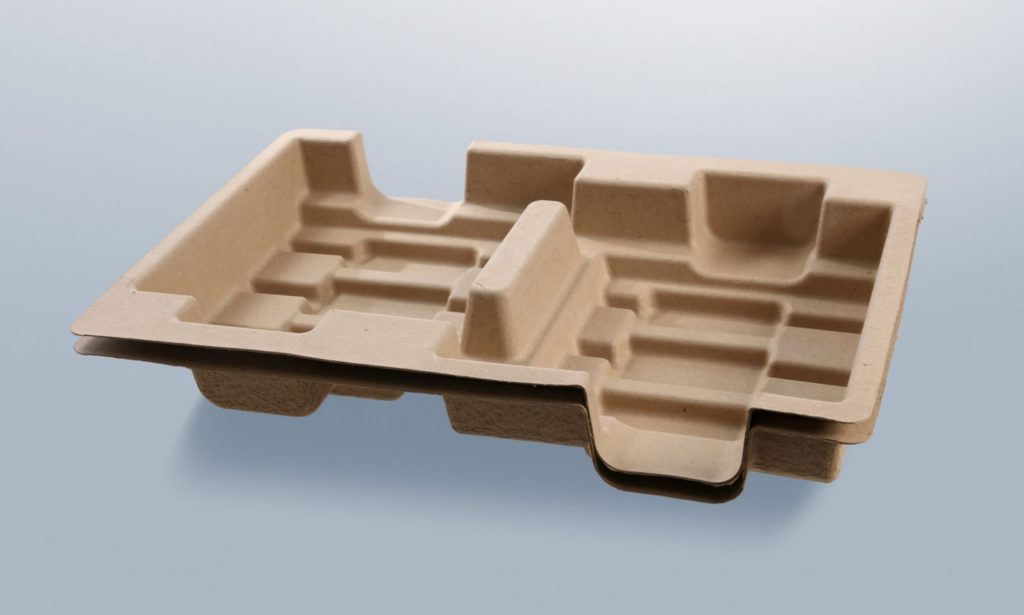

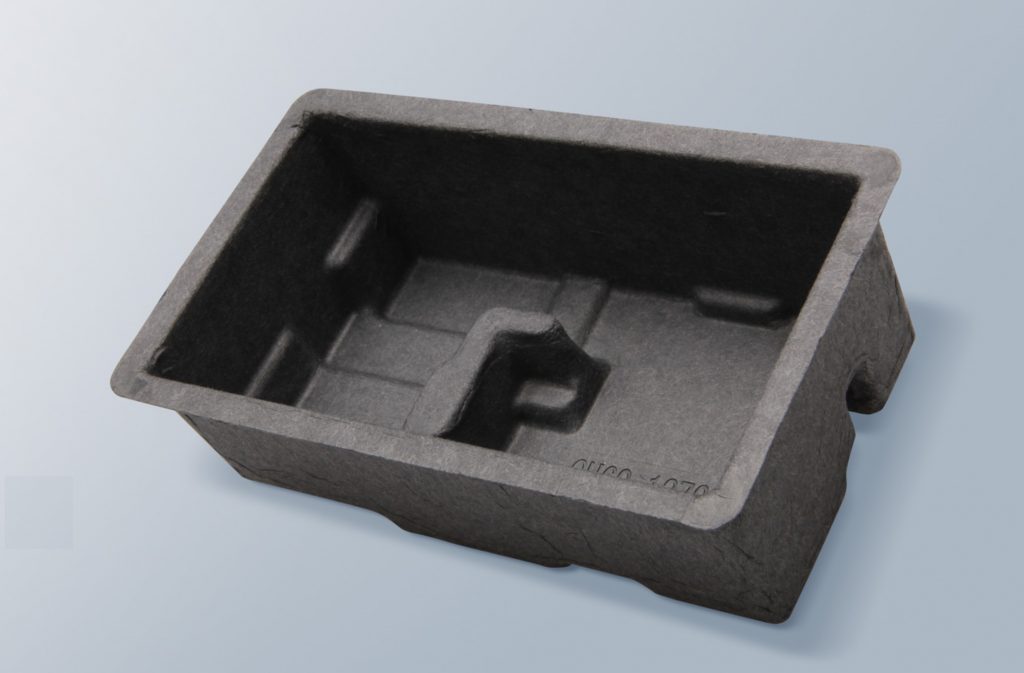

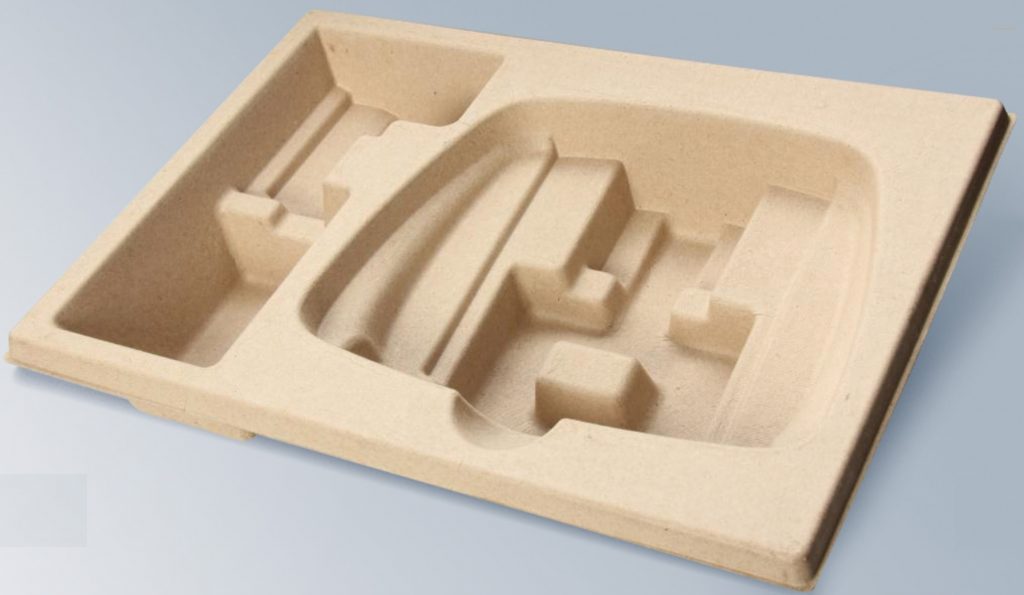

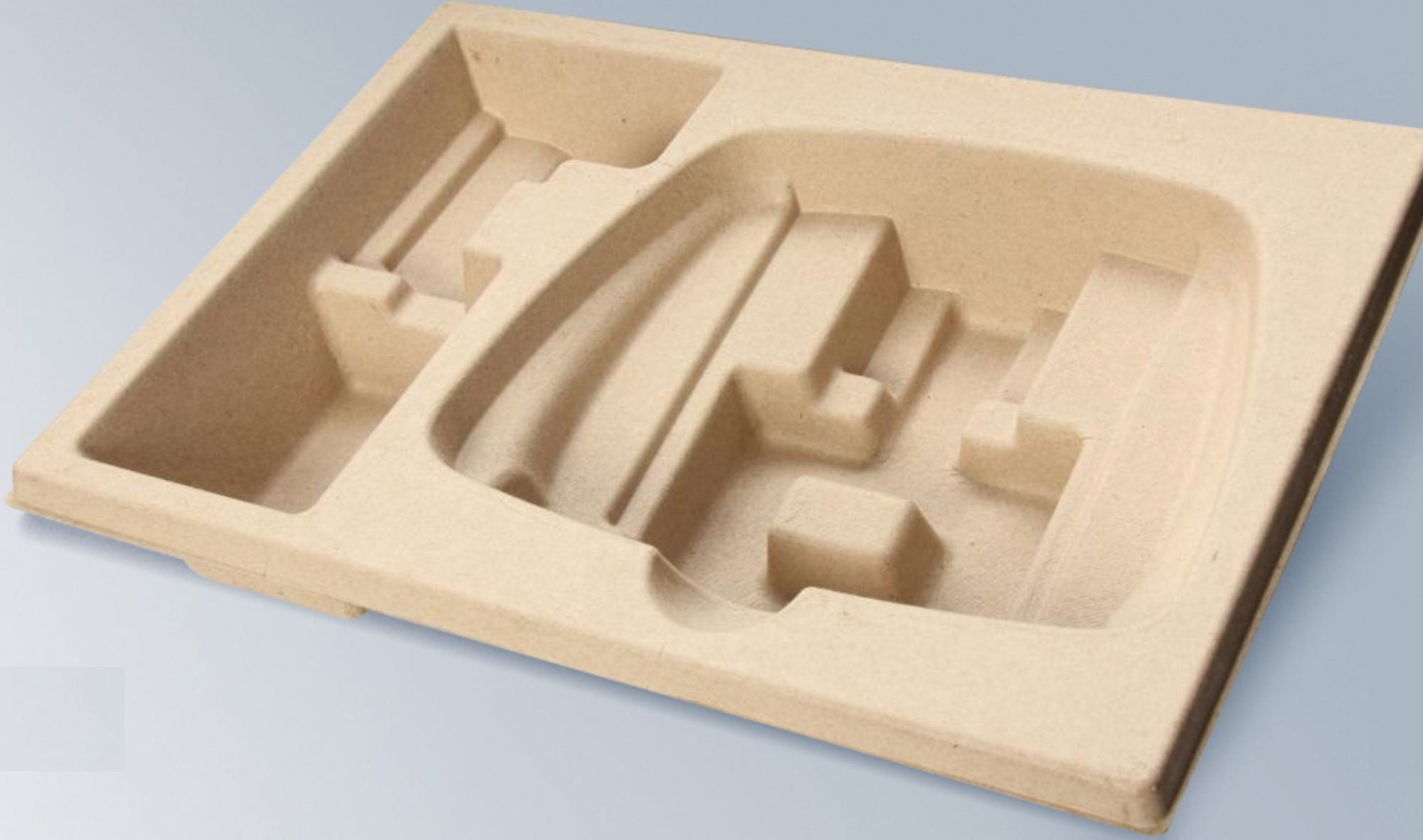

At Pakeling, we offer a new generation of molded fiber and molded pulp packaging, combining sustainability, functionality, and modern design.

Made from renewable fibers such as recycled paper, agricultural residues, or plant-based starch, our molded solutions are fully biodegradable, compostable, and recyclable — a perfect alternative to traditional plastic or Styrofoam packaging.

Key Benefits of Molded Fiber Packaging

- Sustainable & Biodegradable – Made entirely from natural or recycled fibers; decomposes naturally without leaving microplastics.

- Plastic-Free Alternative – Helps brands meet EU packaging regulations and plastic-reduction goals.

- Custom-Formed for Protection – Molded to fit products precisely, providing excellent cushioning and stability.

- Lightweight & Cost-Efficient – Reduces shipping weight and lowers logistics costs.

- Recyclable & Compostable – Can enter the paper recycling stream or compost systems.

- Thermoformed Aesthetics – Smooth, high-quality surfaces suitable for premium cosmetics, electronics, or food packaging.

- Custom Branding – Embossed logos, colors, and finishes available for a distinct brand identity.

- Temperature Resistant – Suitable for both hot and cold applications in food packaging.

- Scalable & Versatile – Adaptable for small runs or large-scale production across multiple industries.

- Made in Europe – Shorter supply chains, reduced carbon footprint, and full regulatory compliance.

What Is Molded Fiber Packaging?

Molded fiber (also known as molded pulp) packaging is produced by forming a fiber slurry — typically made of recycled paper, cardboard, or plant-based fibers — into custom molds that are then pressed and dried.

The result is a lightweight yet rigid structure that can take on nearly any shape, from protective trays and inserts to food-service containers and cosmetic boxes.

Depending on the application, we offer two main types:

- Traditional molded pulp – perfect for transport and protective packaging.

- Thermoformed or injection-molded fiber – smooth, premium-quality surfaces ideal for retail and high-end products.

Ideal Applications

- Cosmetics & Beauty Packaging – sustainable trays, inserts, and gift box components.

- Consumer Electronics – protective packaging for devices and accessories.

- Food & Beverage – trays, cups, and containers for take-away and delivery.

- Medical & Pharmaceutical – sterile packaging and product protection.

- Industrial & Logistics – protective inserts and transport trays.

Our Approach

At Pakeling, we collaborate with leading European producers to deliver custom-designed molded fiber packaging that meets technical, aesthetic, and sustainability standards.

From concept to finished product, we help brands replace plastic with innovative, low-impact materials that fit a circular economy model.